The "Holy Grail" 3040L CNC (PCB Specialist)

Project Goal: A high-precision, desktop CNC machine optimized for PCB manufacturing (0.8mm drilling, isolation routing) and light aluminum work.

Architecture: Raspberry Pi (gSender) via WiFi → PiBot FluidNC Controller → External Drivers → Industrial Mechanics.

1. Bill of Materials (BOM)

Mechanical Base

- Frame Kit: CNC 3040L (6061/6063 Hard aluminum alloy).

- Table material: 320 * 520mm (20mm aluminum alloy T table).

- Engraving area: 260380110mm

- Z-Axis Stroke: 110mm

- Drive System: 1605 Ball Screws (16mm, 5mm pitch) and HG20 Square Linear Rails on all axes.

- Coupling: 3x Plum couplings.

Spindle & VFD

- Spindle: 1.5kW, 220V, 5A, 24,000 RPM (400Hz) Water-Cooled Spindle (Diameter 80mm).

- VFD: Huanyang HY01D523B (1.5kW, 220V).

- Collet System: ER11 (Upgrade to AAA-Precision collets recommended for PCB work).

- Water pump: 80W, 6M lift with 8mm OD / 6mm ID piping.

Control Electronics

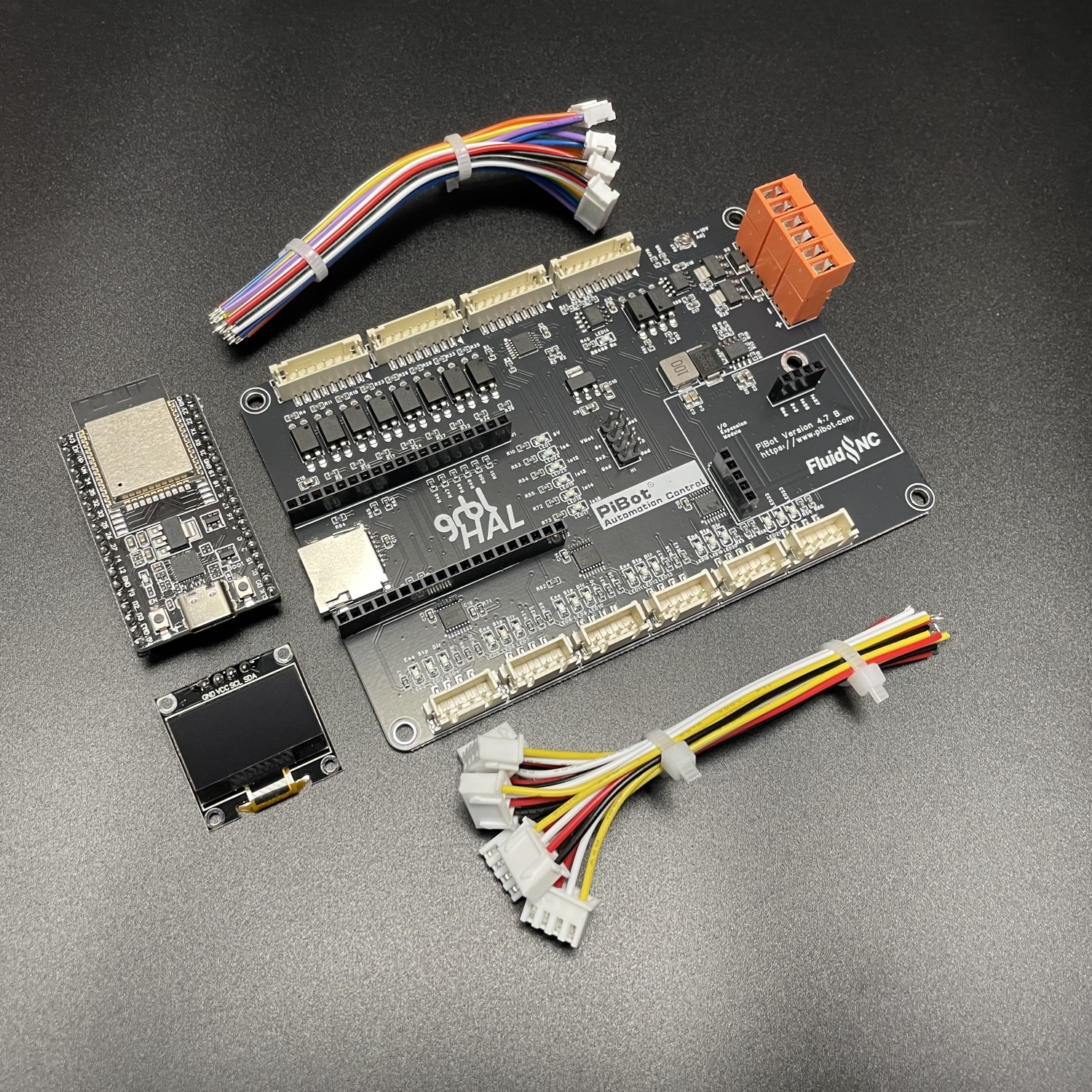

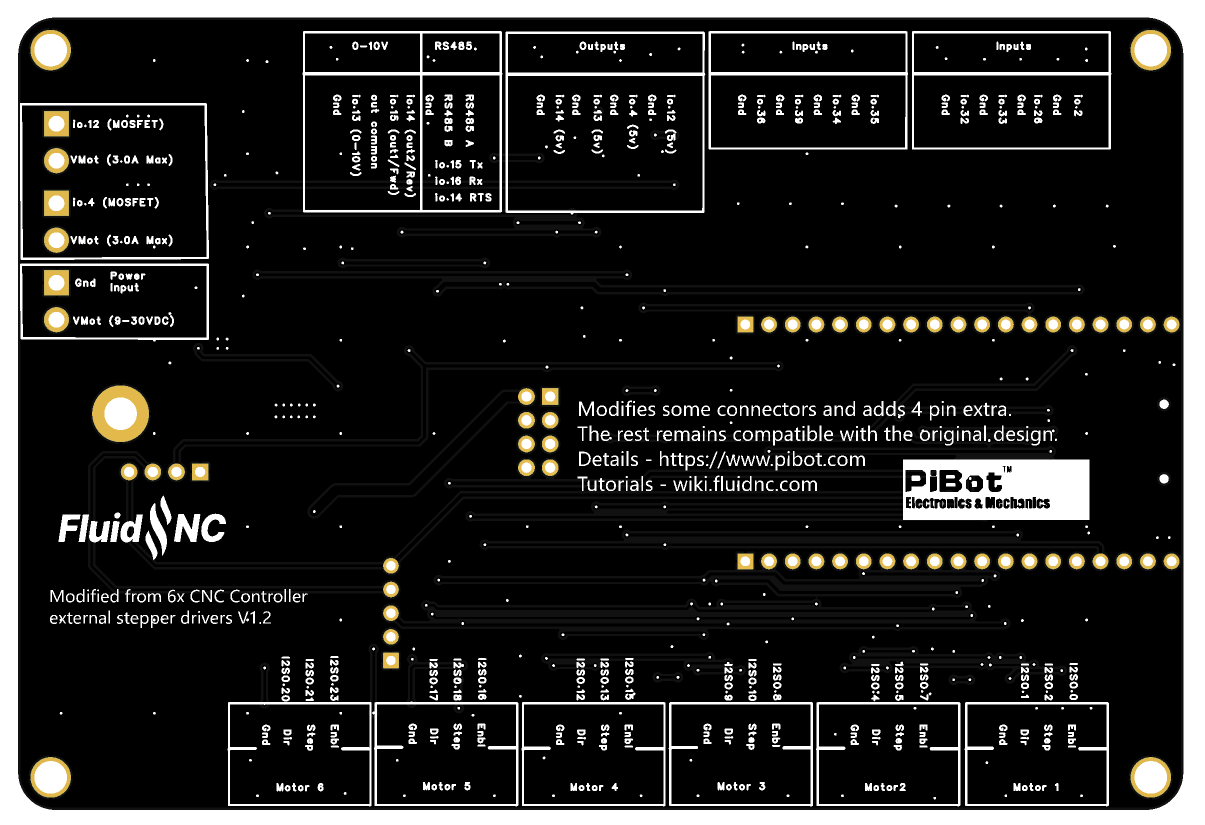

- Controller: PiBot FluidNC GRBL Laser CNC Controller V4.7.

- More info: wiki.fluidnc.com

- Schematics/PCB: oshwlab.com

- Stepper Drivers: 3x DM542 (Digital External Drivers).

- Motors: 3x NEMA 23 57BYGH76 Stepper Motors (3.0A, ~1.5Nm+ torque).

- Limit Sensors: 3x LJ12A3-4-Z/BX (Inductive NPN NO).

- Note: The PiBot V4.7 features built-in 0-10V analog output and opto-isolated inputs, eliminating the need for separate converter modules and isolation boards.

Power System (Dual PSU)

- Motion Power: Mean Well LRS-350-24 (24V, 350W) for Drivers.

- Logic Power: Mean Well MDR-20-24 (24V, 20W DIN Rail) for PiBot Board & Sensors.

Safety & Control Box

- Main Switch: Big Rotary Isolator (Cuts L & N).

- EMI Filter: 250V 10A + IEC C19 Socket + T10A Fuse.

- Main Contactor: 4-Pole AC Contactor (24V DC Coil).

- VFD Breaker: Jotta C10 (2-Pole DIN Rail MCB).

- Buttons: Green (Start NO), Red (Stop NC), E-Stop (Mushroom NC).

Cooling & Accessories

- Coolant: Distilled Water (80%) + Automotive Antifreeze G11/G12 (20%).

- Flow Sensor: HT-30 (G1/2") wired to VFD "External Fault".

- Probe: GX12-2 Connector + Touch Plate.

- Laser (Optional):

- 405nm (500mW): For curing Solder Mask / Dry Film Photoresist.

- Buck Converter: 24V to 12V (if laser is 12V).

2. Wiring Schematics

A. Power Flow (Input)

- Wall (230V) → IEC Filter → Main Rotary Switch.

- Rotary Switch → Small 20W PSU (Logic Power).

- Small PSU (24V) → Start/Stop Buttons → Contactor Coil.

- Contactor (Power Contacts) → Big 350W PSU & VFD Breaker.

- VFD Breaker → VFD Input.

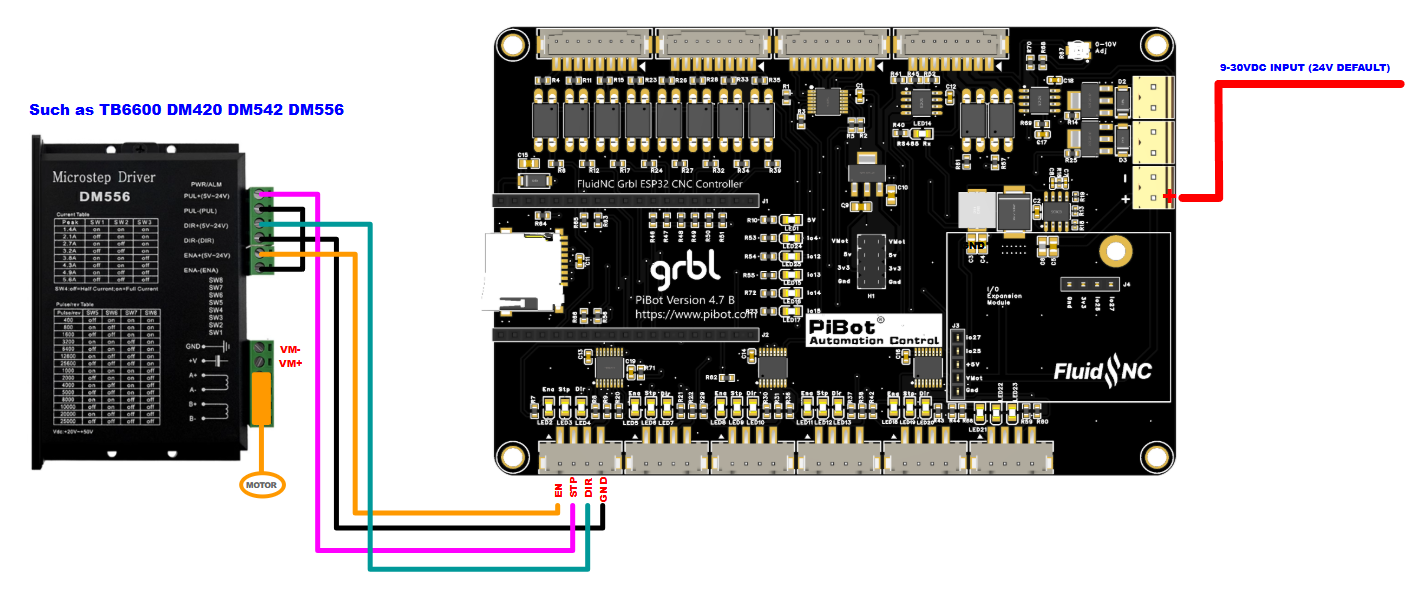

B. PiBot V4.7 to DM542 Drivers

The PiBot V4.7 uses 5V logic shifting for axis signals. The following diagram illustrates the Common Ground (GND) wiring logic used in this build.

| PiBot Axis Header | Wire Color | DM542 Input | Function |

|---|---|---|---|

| STP | Green | PUL+ | Step Signal |

| DIR | Blue | DIR+ | Direction Signal |

| EN | White | ENA+ | Enable Signal (Optional) |

| GND | Black | PUL- / DIR- / ENA- | Common Ground |

C. DM542 DIP Switches

Settings optimized for NEMA 23 and High Precision PCB Work (1/16 Microstepping).

1. Current Settings (SW1 - SW3): Target 2.84A Peak.

- SW1: ON, SW2: ON, SW3: OFF (Recommended Start).

2. Idle Current (SW4):

- SW4: OFF (Half Current - reduces heat when the machine is idle).

3. Microstepping (SW5 - SW8): Target 3200 Pulse/Rev.

- SW5: ON, SW6: ON, SW7: OFF, SW8: ON (Result: 640 Steps/mm with 1605 screw).

D. Spindle Control (0-10V Direct)

The PiBot V4.7 includes an integrated 0-10V circuit.

1. 0-10V Signal Connection Locate the 10V Spindle Interface terminal on the PiBot.

| PiBot Output | VFD Terminal | Function |

|---|---|---|

| 0-10V | VI | Analog Voltage Control |

| GND | ACM | Analog Common |

| out1/Fwd | FOR | Forward Signal |

| out2/Rev | REV | Reverse Signal |

| out common | DCM | Digital Common |

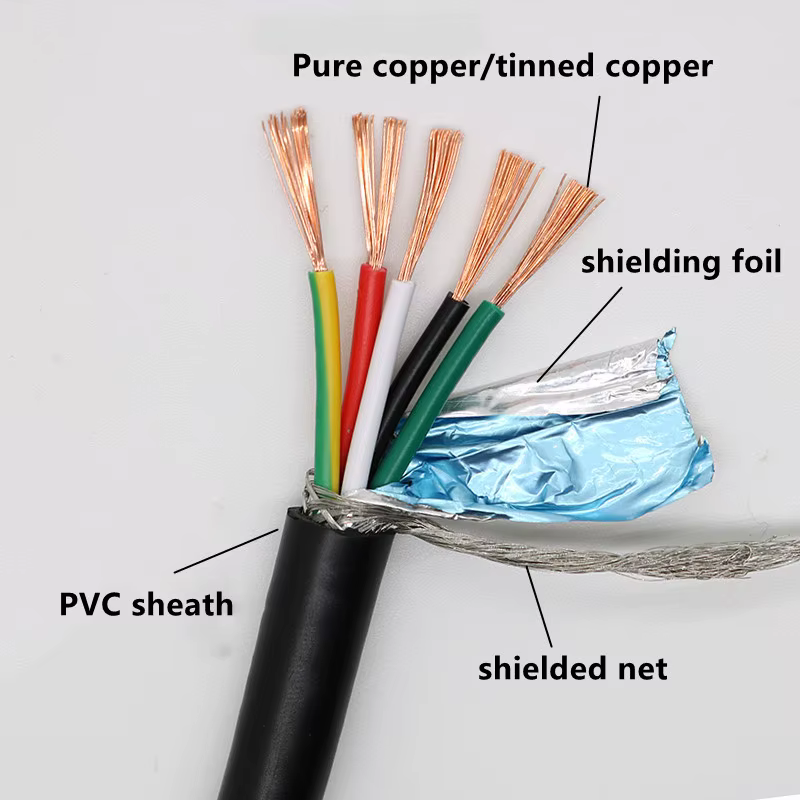

2. RS485 Implementation Detail (4-Core Shielded)

It allows for digital precision (no voltage drift), real-time RPM feedback, and the ability to monitor VFD temperature and current via the FluidNC Web UI.

To ensure zero-error communication at 24,000 RPM, the RS485 cable must be paired as follows:

- Signal Pair: [RS+] and [RS-] must share a single twisted pair to maximize differential noise cancellation.

- Reference Pair: Both wires of the remaining twisted pair are joined for [GND] to provide a stable common-mode reference between the PiBot and VFD logic.

- Shielding: The drain wire/braid is connected to the VFD Earth terminal (PE) only. The PiBot side of the shield is left floating (cut and insulated) to prevent ground loops.

- VFD Config (Huanyang): Set PD001=2 and PD002=2 for RS485 control. Set PD163=1, PD164=1, PD165=3 for 9600 baud communication.

- Wiring: PiBot [A] → VFD [RS+] PiBot [B] → VFD [RS-] PiBot [GND] → VFD [DCM] (If required) Shield → VFD PE (Earth Ground screw)

E. Probe (GX12)

- Pin 1 (GND): Alligator Clip.

- Pin 2 (Signal): Touch Plate (Connect to PiBot Probe Input).

- Safety: Confirm continuity from spindle bit to ground before probing.

3. Cables & Connectors

Proper shielding is critical to prevent EMI from the VFD from interfering with the limit sensors or stepper signals.

- Spindle: GX20-4 (Double shielded TRVVP 4x1.5mm²). Note: High-flex, oil-resistant for drag chains.

- Motors: GX16-4 (Double shielded RVVP 4x0.5mm²).

- Sensors/E-Stop: GX12-3/GX12-2 (Shielded RVVP 0.3mm²).

| TRVVP (High-Flex Drag Chain) | RVVP (Standard Shielded) |

|---|---|

|

|

4. FluidNC Installation & Configuration

- Download the latest release from FluidNC GitHub.

- Unzip and run:

./erase.sh ./install-fs.sh ./install-wifi.sh - Use

fluidterm.shto set your WiFi:$STA/SSID=MyWifiSSID $Sta/Password=YourPassword - Configuration: Upload your

config.yamlusing the Web UI (usually at192.168.1.xxxor viaCTRL+Uin terminal).- Note: Ensure the Pin mapping in

config.yamlmatches the PiBot V4.7 PCB silkscreen (e.g., Step pins, Dir pins, and the 0-10V pin).

- Note: Ensure the Pin mapping in

5. First Run Checklist

- Unlock: Send

$Xto clear<Alarm>. - Sensors: Trigger limit switches manually; verify

Pn:X/Y/Zin console. - Spindle VFD:

- Program VFD parameters (see Section 7).

- Check Water Flow

- Test

M3 S12000for 50% speed (200Hz).

- Probe: Test contact with a multimeter/console before performing a Z-zero.

6. Complete VFD Settings List (Huanyang HY01D523B)

For 1.5kW, 220V, 400Hz spindle:

| Parameter | Description | Setting | Notes |

|---|---|---|---|

| PD013 | Factory Reset | 8 | Clear old data first. |

| PD005 | Max Freq | 400.0 | |

| PD004 | Base Freq | 400.0 | CRITICAL: Do not leave at 50/60. |

| PD003 | Main Freq | 400.0 | |

| PD011 | Min Freq | 100 | Lowest spped 6,000 RPM Safety Limit |

| PD141 | Rated Voltage | 220 | |

| PD142 | Rated Current | 5 | |

| PD143 | Motor Poles | 2 | High-speed CNC spindles are 2-pole. |

| PD144 | Rated Motor Revolution | 3000 | As calculated above (3000 @ 50Hz). |

| PD002 | Freq Source | 1 | External Terminal (0-10V). |

| PD001 | Commands Source | 1 | External Terminal (FOR/REV). |

| PD070 | Analog Input | 0 | 0-10V (Standard for PiBot). |

| PD072 | High Analog Freq | 400.0 | Scales the knob so "Max" = 400Hz. |

For advanced spindle control, see FluidNC Spindle Config Documentation.